In this set of articles, I am going to make an attempt to fully explain just how a diffuser produced tequila is different from a traditionally produced one. Unfortunately the industry does not do any sort of distinction between traditional and diffuser produced tequilas and we have no legal information on which products apply the blend of both worlds.

I hope that by showing people how diffuser tequilas are made, and the cost at which efficiency comes, some consumers may start to understand the business more and appreciate authentic tequilas for what they represent and find it a worthy cause to support producers representing the cultural and traditional heritage of producing distillates capturing the flavor and aroma essence of the agave. The other goal of these sets of articles is that I hope that people would raise their general expectation from the flavor profile of a “traditionally produced tequila” as opposed to a “diffuser tequila” or tequilas that can potentially be “diffuser/traditional blends”. Modernization is part of life and there is nothing we can do about it – however we can educate ourselves to understand that with every purchase we make, we shape the future of the tequila industry.

What is a Diffuser?

In a nutshell, diffuser is basically a large metal box with a conveyor belt inside which allows producers to achieve an over 95% efficiency sugar extraction. Instead of applying mechanical pressure like in the traditional method, producers use hot water to wash every ounce of sugar out of the agave fibers. Since producers need sugar to convert to alcohol, this efficiency is handy when it comes to producing tequila on a large scale. On top of this, the diffuser technology allows tequila producers to produce tequila in a modern, controlled environment. After harvesting the agave, the harvested balls are put on a conveyor belt and no “human hands” would ever touch the product again until it has been bottled.

Efficiency, Efficiency and Efficiency

The key to producing diffuser tequila is efficiency. There are three major types of efficiency. The sugar efficiency is omnipresent and is the primary purpose of the diffuser process. There are 2 other efficiency factors (time and control) that are usually associated with the diffuser process itself in general, however they are more like its mass production related side effects.

- Sugar / Ethanol efficiency (primary purpose): producers need less agave to produce the same amount of tequila. As a result, the product would carry less taste of the ingredient - the blue agave.

- Time efficiency (secondary purpose): Time is money. Producers don’t bother “wasting” time on removing impurities such as wax and dirt from the agave fields which are removed as “bitter honey” by the traditional processes and there is the potential use of sulphuric acid to make the hydrolysis quicker, extra fast fermentation and distillation etc.

- Control efficiency (side effect): Producers want to have a great degree of control over the taste of their tequila. The easiest way to create a consistent flavor for a tequila product line is by blending traditional tequila with diffuser, utilizing extensive filtrations and using additives.

Sugar / Ethanol Efficiency

As it takes 5-6 years for the agave plant to properly mature from its time of plantation, there is a certain inventory issue when it comes to tequila production. There are certain periods when there is just not enough agave to supply for a global demand, so producers are looking for ways to make the production more efficient – in other words to be able to create more bottles of tequila from the same amount of agave.

Let me start the explanation with a quote from Carlos Camarena, producer of Tapatío, Ocho and El Tesoro tequilas:

“If sugar was the only important element, remember – sugar converts into ethanol. So what about the aromas and flavors that are not only alcohol? Alcohol by definition doesn’t smell good and doesn’t taste good. But all of those other aromas and flavors will come mainly for the acidity of the plant or other parts of the plant, which are not related to the sugar content.

Peruvian Pisco producers have a traditional aromatic product called “mosto verde”. They only half-ferment(!) their mosto so that less sugars convert to alcohol meaning they would use double the amount of grapes that were already carefully extracted! They are not crazy people, they know exactly that in return of an inefficient process, they would increase the concentration of the grape parts and juice so they would get more natural grape aroma and flavor!

As you can see from the above examples, producers can decide to focus on sugar / ethanol efficiency to increase the concentration of alcohol in their spirits and as such focus on volume or they can choose to be “inefficient” and increase the concentration of flavors and aromas in their spirit.

This is exactly what happens in case of a “mixto” tequila. If you compare the taste of a roller mill produced 100% agave tequila and its 70/30 “mixto” variant, the two tequilas will share many tasting notes, however the one with 30% non-agave related sugar content would have a lighter and less complex aroma and taste profile. The explanation to this is that while producers extracted the 70% agave sugar part along with “agave parts” including its flavors to be included, the 30% sugar part usually has very few aroma components. As such it will convert to extra ethanol, increasing mostly the alcohol concentration of the spirit without contributing much to the flavor, reducing the proportion of the “agave parts” that were extracted naturally from the agave plant. For this reason some producers (see El Tequileño as a great example) may use “aromatic” sugars like piloncillo to add some complexity or extra natural flavors/aromas to their mixtos. Also, according to Sergio Cruz, master distiller of Viva Mexico some sugars like sugarcane has a higher ethanol conversion efficiency than agave during fermentation. He also kindly explained that the extra sugars extracted by the diffuser come with other particles that has an effect on the flavor – it is hard to tell if they are beneficial or not, but they do have an effect on the flavor profile.

The extra sugar efficiency of the diffuser process works in a similar way as in case of a “mixto” (category Tequila), the most important difference we are going to analyze is that the extra extracted sugar content increasing the concentration of alcohol is agave related, meaning the product can be called 100% agave.

This increased Sugar / Ethanol efficiency is not only contributed to diffuser as an extraction method, but for the whole process chain. As Sergio Cruz pointed out, diffuser producers typically pair diffuser with other processes and equipment so they can maintain an efficiency as close to 100% as possible through the whole process, not just the diffuser part. Traditional producers leave the fermentation tank open, so the ethanol evaporates, and in a traditional approach it can take over a week, especially during winter months. Diffuser producers use closed fermentation tanks to avoid evaporation and they deliberately use yeasts that are more efficient in generating more ethanol (by applying yeasts that are resistent to low pH and high abv %) leaving less residual sugar. Then traditional producers lose some ethanol concentration with the pot stills as they make their cuts from head to heart to tail – diffuser producers using column stills are not limited by this inefficiency.

Let’s do some math to understand just how much efficiency we are talking about exactly in case of different production methods.

The numbers represent more like a “benchmark” rather than the absolute truth. The calculation is based on our interviews with roller mill and tahona user producers and may not represent the industry as a whole. The individual fermentation and distillation decisions made for different brands within the same distillery just alone have an effect on the agave use. We don’t have a lot of visible data for diffusers, but Casa Sauza has provided official information we could use – they can reach over(!) 95% sugar extraction efficiency in the case of their diffuser process. This is the number I’ve used for my calculation. I made the assumption that this min. 95% efficiency can be maintained throughout the whole process in combination with the other processes. I was using a 24 ART (Azucares reductores total, total reducing sugars) agave to calculate the diffuser’s agave usage. This seemed to be an appropriate choice for the comparison, especially that a diffuser can likely be more efficient when using a higher sugar content agave with proportionately less fibers.

I was using the universal C6H12O6 >> 2 C2H5OH + 2 CO2 formula to determine how much sugar would be needed for the diffuser.

180.16 g/mol fructose >> 2 * 46.07 g/mol ethanol + 2 * 44.01 g/mol carbon dioxide. So in effect the conversion rate would be 92.14/180.16 = 0.511 ethanol/fructose. I have found some articles with higher numbers then this in some articles, but I’ve found this calculation to be the most prudent to use.

I believe the numbers make sense from a business perspective, still inaccuracies may remain – as such feel free to reach out if i missed anything.

approx. 10 kg agave >>> 1L 55% – Based on interviews. Some producers may use significantly more agave due to a less efficient process, so in those cases, this figure can even be higher. I personally expect this figure to have the highest variation between producers due to the many individual decisions observed like fermenting/distilling with or without fiber, the material of the fermentation vessel (wood, concrete, stainless steel) and a larger than usual range of still strength of such products meaning different distillation cuts.

To get 40% abv, 750mL tequila – 10 / 55 * 40 * 0.75 = 5.45 kg

Approx. 8.25 kg agave >>> 1L 55% – these paramaters are based on interviews with producers. Some producers may use more / less agave.

To get 40% abv, 750mL tequila – 8.25 / 55 * 40 * 0.75 = 4.5 kg

In an ideal environment 550mL ethanol weighs 550*0.789 = 433g. To create 433g ethanol, we would need 433 / 0.511 = 847 g sugar and so 0.847/0.24 = 3.53 kg (24 ART) agave. Let’s assume a 95% efficiency 3.53 / 0.95 = 3.71 kg agave to get 1L 55% abv tequila. This number is slightly lower than the unofficial range of 4-5 kg, however diffuser producers have been called out for using immature agave with lower sugar content, especially during an agave crisis – lower sugar content agave would mean more agave used. That would not have been a fair comparison. We requested a few distilleries to let us do a tour in their facilities to verify this and do an interview with someone in charge of production, but our requests were denied unfortunately.

To get 40% abv, 750mL tequila 3.71 / 55 * 40 * 0.75 = 2.02 kg

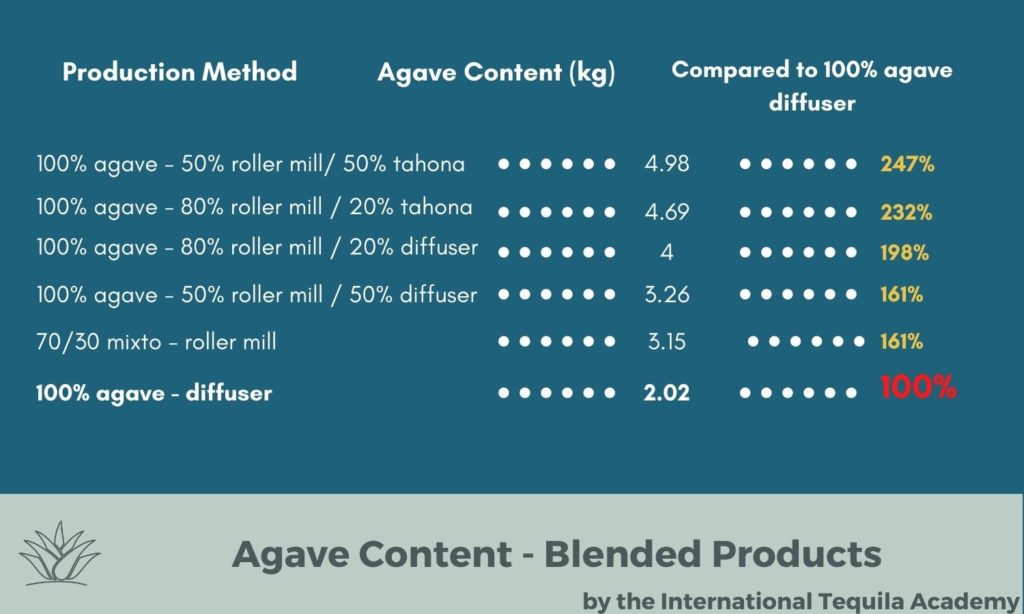

Tequilas made by tahona or roller mill extraction methods (coupled with other inefficient processes) use more agave, have a higher “agave aroma concentration” carrying more of the agave’s natural aromas and flavors. As such it would be great for us consumers if diffuser products would have a different designation or category statement. Now that the diffuser technology is allowed, “100% agave” no longer carries the same weight as it did when it was implemented – a tahona or roller mill crushed traditional tequila is literally “200%+ agave” vs. its diffuser “100% agave” counterparts. (see the charts below for more comparisons)

Have you ever wondered why some traditional producers can make very decent “mixto” tequilas that can surpass the quality of some “100% agave” products?

The answer is quite simple if we accept the fact that at the most basic level, the professional quality of tequila correlates with the amount of agave used in the production. A roller mill 70/30 mixto would still give us 4.5 * 0.7 = 3.15 kg agave used vs. 2.02 kg, which is still over “150% agave” tequila compared to a “100% agave diffuser” tequila. The agave use of an “authentic” 51/49 mixto is still slightly more, 2.3kg vs. 2.02 kg in case of a diffuser. So yes, a traditionally made “mixto” tequila can easily match a “100% agave” diffuser product when it comes to natural agave taste and if made the right way, it can even surpass it.

Then there is an invisible middle ground too between diffuser and traditional tequilas – the blend of the two. By creating a blend of 50% diffuser, 50% roller mill would leave us with 3.26 kg agave, which is almost the same agave content as in the case of a 70/30 roller mill extracted mixto tequila 3.15 kg. Blends (from the producers own site or with tequilas from other producers) are perfectly viable according to the norma and we will catch up on this in a later article potentially.

You can use the charts below to compare different production methods and blends as to how much agave is used in them vs. a 100% agave diffuser tequila.

Conclusion

Diffuser – concering its sugar / ethanol efficiency creates a different flavor profile with a higher alcohol concentration similar to “mixto” tequilas but with a different flavor profile. Less aroma rich agave parts, less “agave essence”, higher ethanol concentration. The reason why they initially implemented the 100% agave category was not to separate the bad guy and the good guy, but to give consumers the opportunity to buy and support a product with more agave in it, a product with a special distinction that can be considered traditional. Sadly, with the newest extraction method called the diffuser, the norma did not keep up with properly informing us consumers by adding separate labeling terms and so now we have to rely on our education and palate to be able to properly select those tequilas that give us the real cultural experience.

Stay tuned for the second part about the “secondary purpose” and “side effect” of using a diffuser!

Resources

If you want to learn more, there are other authors like Mucho Agave and Vancouver Guero explaining the process itself with some other details with further information, many consider these two articles to be a must read on the topic. I also have a lot of respect for Lou Agave’s reviews – he is fully independent, happy to go against the general consensus if it doesn’t make sense so he may help you identify potential diffuser blending. Also I personally consider the TMM app and website as a great help too in this sense, if a producer have diffuser at their site it will have a remark about it at the process detail and you can also look for suspiciously low scores – they too may indicate potential diffuser use. Sadly, one can only speculate when it comes to diffuser blending, but the aforementioned resources may help you get a better grasp of the topic. They are all authors and materials supporting small, independent and authentic tequilas, so I’m happy to refer them. If you want to learn how the traditional tequilas are produced, we did several interviews with our tequila heroes, you can find them here. You can learn more about the amazing and extremely traditional spirit of Pisco by doing the Pisco Certificate course, I’ve personally learnt a lot from it, a big shoutout to their passionate team! And finally you can learn many more interesting details about tequila including diffusers through the tequila courses we offer.